Restoration Framing on Heritage Farmhouse – Priceville, Ontario

This stage of our Priceville farmhouse restoration involved rebuilding from the foundation up—literally. The original stone and block foundation was far from level, which is typical of heritage homes in rural Ontario. We installed new pressure-treated sill plates and used non-shrink grout to fill irregular gaps, creating a solid, level base for framing. This is where restoration meets precision carpentry—laying the groundwork for a stable, long-lasting rebuild.

To protect the new structure from moisture over time, we installed gasketing between the pressure-treated sill plates and the existing foundation. This prevents future rot and ensures long-term durability. As general contractor and builder on this project, JCB & SONS is handling every phase—from teardown to rebuild—with care, craftsmanship, and the experience needed to renovate historic homes properly.

New jack posts were installed on new footings and we installed a new flush beam for the floor which won't interfere with the air flow of the new HVAC system. All the joists were installed with proper joist hanger brackets and engineered nails.

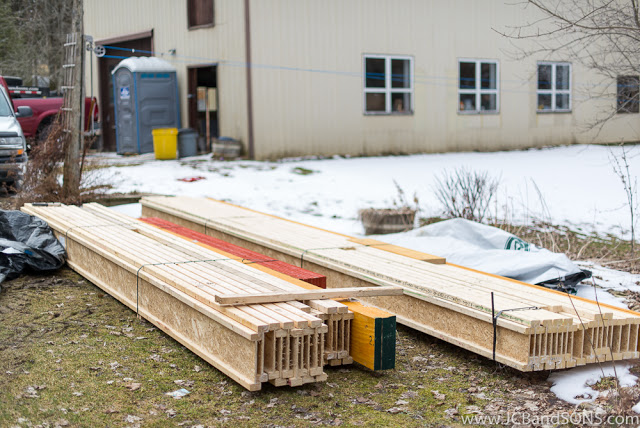

We will be using engineered Wood I's for the second floor, floor joists and the addition ceiling joists as they can clear span unsupported allowing the home to not have unsightly beams which would also interfere with duct work.

Gabriel and Jude are the Saturday crew and love to help make the dump runs.

We studded in the old basement and it's ready for the new polyurethane spray foam.

The old sheathing on the house was moldy and had to be removed, this also gave us the opportunity to use our tractor to pull the addition plumb as it was out a 1/2" and would make installing cabinets a problem had we not.

The new 5/8" tounge and groove sub-floor is glued and screwed to ensure no squeaks in the home.

This quick drive makes installing the sub-floor a breeze with its auto feeder.

LVL beams were installed in the second floor for the new stairs so that absolutely no walls or posts are needed in the room

The picture window in the old farmhouse was not original to the home, it also didn't match the height of the other windows and the lintels were installed improperly. We opened it back up and installed new lintels that were welded together for added strength.

The new ceiling joists are in so the roof sheathing was reinstalled and Grace Ice and Water Shield has been installed ready for the new shingles.

The new Wood I's are installed in the addition of the home allowing for an open concept kitchen and 10'-0" high ceilings too.

Also check out our latest video post:

Farmhouse Demolition & Tear-Out – Priceville Restoration Project

This heritage farmhouse restoration in Priceville, Ontario kicked off with a full-scale tear-out. The original structure—typical of century homes in Grey Highlands—required extensive demolition down to the double brick. We removed failing finishes, stripped out old framing, and exposed the bones of the building to prepare for a structural rebuild. It’s always humbling to see just how much work these rural restorations demand, but that’s where our background in heritage carpentry comes through.

Whether it’s brick farmhouses near Flesherton or full rebuilds in West Grey, JCB & SONS brings the right tools and trade knowledge to restore these homes with care and long-term integrity. This project is just getting started, but the vision is clear: rebuild it right, and bring it back stronger than ever.

The addition foundation has some cracks in it and is leaking, so this will get the full treatment during our project to fix all these problems.

The old electrical fuse panel is outdated, broken, and almost completely rusted out.

The house is a double brick construction, there are no studs. They walls were strapped and than lathe and plaster was put on. We have stripped it right back removing everything. We will install a new floor system, and install new studs to allow for proper insulation, modern wiring, and a place to route the plumbing and duct work for the heating and ventilation

Lot of bracing was installed to keep the home secure while the floors are removed and reconstructed.

One of the things that is really important to our customer is air quality. Air quality is important in every home, but in this situation some of the family are exceptionally sensitive to air quality. This addition had never received a vapour barrier, in fact the opposite - they put a plastic wrap on the outside forcing the house to condensate. You can see that it has caused a mold on the exterior wall sheathing. The sheathing will be removed and the house re-sheathed ready for new siding. We will also be using polyurethane spray foam on this home.

The old floor joist are full of dry rot, they aren't level, and also can't span the distance they are spanning. We removed them to install a new level strong floor.

We installed footings to carry the new floor going in, and than put in washed stone to pour the new cement floor on.

This is the plastic wrap they put on the outside of the home causing the mold on the inside of the home. It will all be removed. Also the cement block foundation was never parged. We will be digging this up to parge it and install a waterproofing.

Check out our video posts of the progress we have made on this project.

Custom Stair Railing & Millwork Project – West Grey Carpentry Build

We recently wrapped up a custom stair and railing project in West Grey, near Durham and Hanover—showcasing the kind of finish carpentry we’re known for. This build included hardwood ash stairs, hand-built newel posts with custom caps, detailed bullnosing, and rod iron railings that brought strength and style together. All millwork was crafted in our shop and installed with precision onsite, delivering a finished product that blends structural integrity with refined craftsmanship.

Farlow’s Home Hardware in Durham created a custom stain for us to match the client’s kitchen cabinetry, helping the new stairs tie seamlessly into the home. Whether you’re renovating in Flesherton, West Grey, or near Owen Sound, we specialize in stair upgrades, custom railings, and detailed interior woodworking. JCB & SONS brings true craftsmanship to every trim and finish job—built to last and designed to fit your space.

The railings were mortised to take a special hidden super strong fastner to attach them to the newel posts and leave a very clean finish with no seen flush cut plugs or nails of any kind.

We had a lot of fun custom milling these really unique post caps for this project in our shop.

All of the mortises for the square spindles in the stair stringers were cut by hand on site to receive these really unique rod iron spindles. If you haven't had the opportunity to see some of our video's of some of the process involved with this project check them out on youtube.

Part I

&

Part II