West Grey Finished Basement Renovation – JCB & Sons

This basement renovation in Durham, West Grey brought together a custom home office and theater room in one cohesive space. Featuring detailed trim work, clean drywall finishing, and built-in media framing, it reflects the kind of practical, high-quality renovations JCB & Sons is known for. As licensed carpenters and home improvement contractors serving the Owen Sound area, we take pride in finishing the job right, down to the last detail.

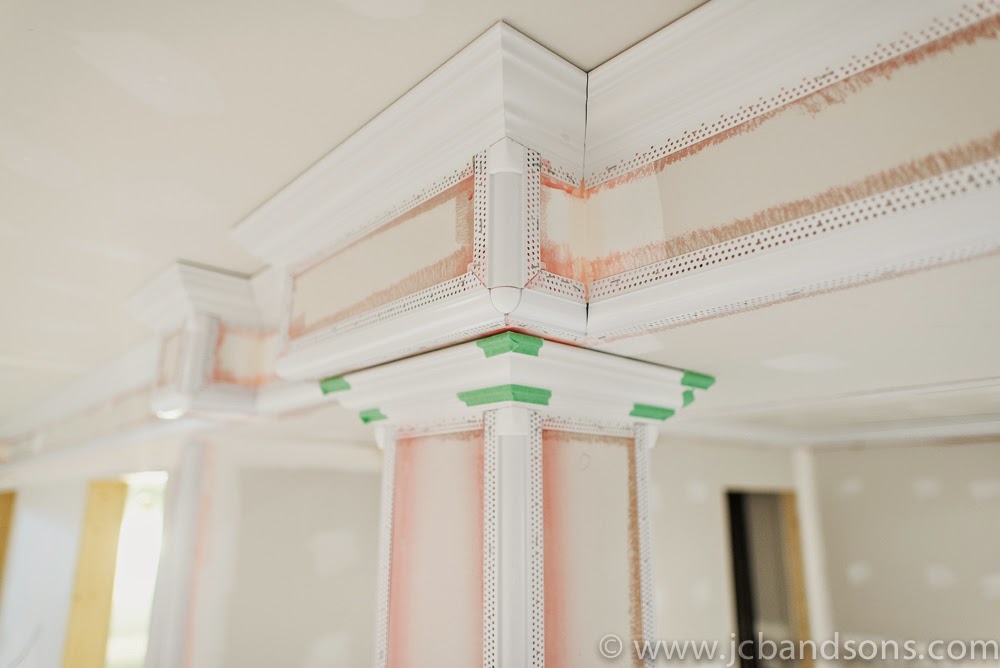

These finished columns were detailed with stepped bullnose edges and integrated crown moulding for a clean, modern look. We installed dimmer switches for the LED pot lights directly into the column near the stairwell — an ideal placement for controlling lighting and creating a true home theater atmosphere. As always, the finish carpentry and layout were tailored to the space and built by JCB & Sons.

This new office area was designed to support focused work while remaining connected to the main living space — ideal for family life. We integrated audio/visual capabilities and ran dedicated network and phone lines to ensure reliable, hardwired connectivity at the desk. It’s a functional, streamlined workspace built with everyday use in mind.

This bulkhead and column detail shows how thoughtful trim design can transform even basic framing into a polished architectural feature. While we used manufactured profiles at the time, we now produce our own custom mouldings in-house, allowing us to create one-of-a-kind finishes tailored to each project.

This custom bulkhead was built above the home theatre screen to create a clean visual accent and define the space. It also offers a discreet location for a future motorized projector screen, combining both function and form in the design.

All of the trim and Doors received at least 2 coats of Beauti-Tone Designer Series Trim & Door paint.

We installed six-panel doors with hinges hand-mortised into clear pine jambs, milled right in our shop. We believe in using solid wood for all our door jambs to ensure strength, longevity, and a finish that holds up over time.

For the storage access under the stairs, we fitted a clean slab door, custom-cut to match the angle of the stair stringer. While a panel door wasn’t feasible in this case, the solution kept the lines consistent and functional. Today, we have the ability to build fully custom angled doors in-house when needed.

We prepped this corner for a future propane wood-stove by running the gas line, thermostat wire, and tiling the hearth area. The nearby electrical outlet is tied into our backup generator panel, allowing the stove’s fan to operate during power outages. This setup provides both a primary heat source and a reliable emergency backup — designed with long-term functionality in mind.

This is the completed spare bedroom, which includes a concealed sump pump tucked beneath a custom nightstand. The removable top allows easy access to the pump, which is permanently plumbed and wired into our backup generator panel — ensuring functionality during power outages. We also installed a battery backup unit for added protection in case the generator isn’t running. While the home had no sump pump originally, we added one proactively to protect the new finished basement for years to come.

We installed the new HRV system inside the bedroom closet to keep it both discreet and easy to service. Our previous attic-mounted exhaust fan operated on a humidistat but created constant negative pressure — relying on uncontrolled air leaks to function. After upgrading to new windows and spray-foaming the basement walls, the home became too airtight for that system to work effectively. The HRV now provides consistent, balanced ventilation and has been one of the most impactful upgrades of the entire renovation.

This is the installed HRV system, configured with four ventilation lines. Two insulated ducts handle fresh air intake and stale air exhaust to and from the outside, while the remaining two distribute fresh air throughout the home and extract stale air from interior spaces. During the summer months, we can switch the system to recirculation mode to prevent hot, humid air from entering the home while maintaining indoor airflow. It’s an efficient, flexible solution for year-round air quality.

This is the completed bathroom, built using a full Schluter waterproofing system — Kerdi board on the walls and Ditra under the tile flooring — to ensure long-term durability. The shower is prepped for future glass walls and features both a 10-inch rain head and a hand-held shower wand for flexibility. We installed a pressure-balanced valve with an integrated diverter, choosing reliable components with proven warranties to back the finish.

Ceramic tile was also used to create a 4” baseboard around the bathroom perimeter, adding a clean, cohesive finish and improved durability in a moisture-prone space.

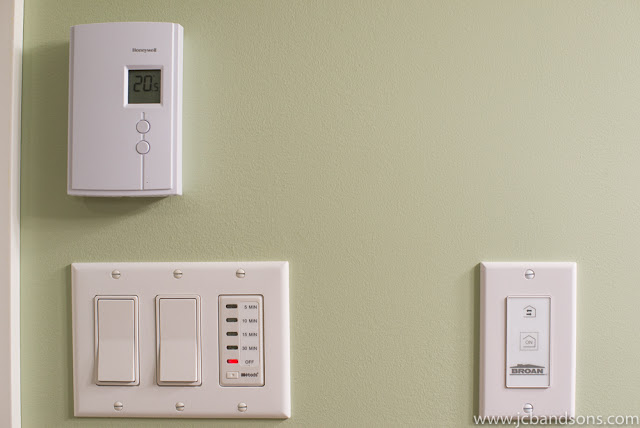

A digital thermostat was installed for the electric baseboard heater, providing precise temperature control in the bathroom. A timer switch controls the exhaust fan to help manage humidity, while a dedicated booster switch activates the HRV system for 20 minutes, efficiently exchanging stale air from the bathroom — and the entire home — with fresh air from outside.

The utility and laundry room was upgraded with a 60-gallon electric water heater, a water softener, and a large capacity pressure tank to provide water storage during power outages. The well pump was wired into the backup generator panel, allowing manual control to recharge the system when needed. A two-stage filtration setup was also installed — with 30-micron and 5-micron filters to reduce sediment — and space was reserved for a future UV purification unit if required.

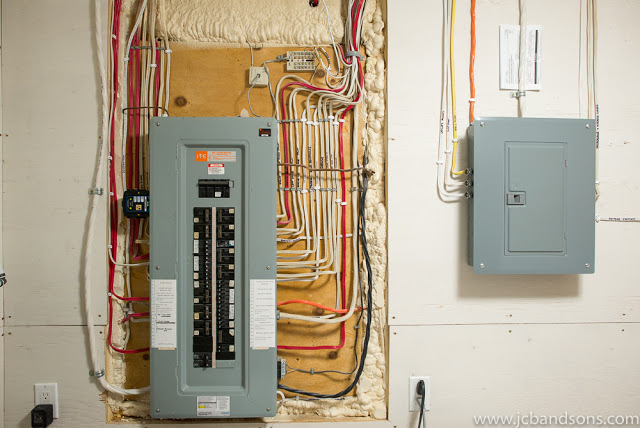

The original ITE breaker panel was retained and supplemented with a complete home surge protector to safeguard all electrical systems from potential power surges. A new Square D generator sub-panel was also installed to provide critical backup power during outages. In rural areas where power failures can be prolonged, these upgrades offer reliable protection and peace of mind.

This basement renovation in Durham, West Grey reflects the level of detail and foresight that defines JCB & Sons. From framing and drywall to mechanical systems, trim work, and integrated backup solutions, every element was approached with long-term function, efficiency, and craftsmanship in mind. As licensed carpenters and home improvement contractors serving the Owen Sound region, we take pride in delivering renovations that are both durable and thoughtfully designed to serve the way people truly live.

Basement Renovation & Drywall Work – Elmwood, Ontario

This basement renovation in Elmwood, just outside Durham, included full drywall installation, finishing, and custom trim work. JCB & SONS handled all stages of the renovation, from board and corner bead installation to crown molding and detailed finishing. We provide licensed carpentry and interior renovation services across Elmwood, Hanover, and the greater Grey-Bruce region—whether it’s transforming a basement or upgrading an entire home.

The posts turned out sharp with the 3/4" Step A Bull and Crown Mold. Once the adhesive is dry on the corners of the crown mold we can remove the green painters tape on the outside corners.

The

we moved into the corner now has

around it with a dedicated GFCI receptacle for the pump inside these, and will be a night stand in this bedroom when it's completed.

We installed

in the bathroom for its mildew resistance. The area that isn't drywalled will be the future tile shower and will be covered with

.

West Grey Basement Renovation – JCB & Sons | Home Improvement Contractor

We’ve been back at our own place, working hard to complete a full basement and office renovation in Durham, Ontario. This home improvement project included a brand-new HRV system, upgraded ductwork, and full framing and bulkhead installation — now moving into the drywall phase.

You can see the main runs of duct work from our brand new

that feed fresh air to our home and remove the stale air, creating a very healthy environment for our family. We framed a bulk head around them to hide the ducting. We absolutely love our new spray foam insulation in the basement, it has been amazingly warm in our house during these freezing temperatures the last few weeks.

This is the utility room with updated plumbing, and a new

that we installed for emergency use.

Here you can see where we installed our new

in the basement bedroom closet. It will be easily accessible to clean the HRV filters every 3 month here and, to do yearly maintenance. It also was an ideal location to run the ducts and it was on an exterior wall so that we can access nice fresh air, and exhaust the stale air.

We now have our sewage pump all hooked up which will handle pumping the waste water from our basement bathroom when it's completed.