Southgate Honey Shed Complete – Pole Shed Renovation & Workshop Build

White has never looked so right on this Southgate honey shed project—now fully wrapped up by JCB & SONS. We installed exterior LED lighting at each major entrance, ensuring safe and practical access for year-round use. This project blends custom pole shed construction, general contracting, and framing with long-term function for a working farm. It’s a clean, bright finish to a purpose-built garage and workshop space tailored to a rural operation.

The original pole shed, now fully studded and wired, will serve as both storage and shop space for the honey business. We spray-foamed the roofline with closed-cell polyurethane to allow insulated storage right up into the trusses. This section is ready for future finishing with a vapor barrier, insulation, and interior liner. Whether you’re renovating an existing shed or building new, JCB & SONS offers complete framing, renovation, and contracting services for agricultural and residential clients across Southgate, Holstein, Mount Forest, and beyond.

Over the utility room and bathroom a strong floor was framed to allow storage of any items that need to be stored up out of the way. An 8'x8' Steel Craft overhead door makes moving product from the extraction room into the storage area very easy. This also makes the extraction room easy to be contained and kept as warm as necessary to make the extraction process run smoothly.

A belt drive power opener was installed on the front overhead door with keyless entry on the outside of the building.

The extraction room received a Trusscore liner which is made local in Palmerston, ON on the walls and the ceilings. This is a food grade product keeping the room bright and making cleaning really easy. A centre gutter drain was installed to allow for washing the equipment and the room.

10' x 9' Steel Craft doors were installed at both ends. All the framing that was exposed was clad in white steel trims to stay with the white theme in the extraction room and also leave an easy to clean surface.

Insulated doors lead to the bathroom and utility rooms which are insulated as well to allow these areas to be heated during the winter. This way the entire building doesn't have to be heated but the water can be left on in these rooms for the winter.

The utility room is lined in plywood to allow the easy mounting of any equipment necessary.

The bathroom we roughed in for the future will be lined with the same Trusscore product that went in the extraction room. It will allow a place to clean up after the extraction process and will even include a shower.

This wall allows for a bug out machine to be controlled by a wall switch. This machine is used to attract any remaining bees to be collected and safely returned to their colonies during the extraction process.

We'd like to give a shout out to all our suppliers. They are awesome!

Trusscore Liner & Interior Prep – Honey Shed Renovation in Southgate

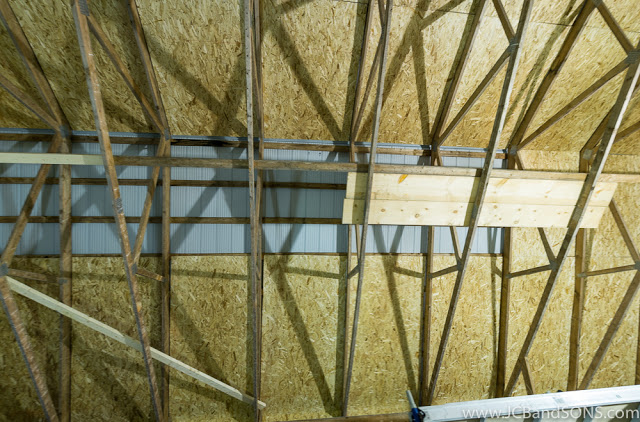

We’ve installed Trusscore PVC wall liners inside the Southgate honey shed build—located between Holstein and Mount Forest, just south of Durham. Prior to spray foam insulation, we sheathed the interior of the original pole shed with 1/4” OSB to create a barrier between the foam and the steel roof. This prep work protects the roof panels from bonding to the insulation and allows for future replacement if needed. Both the existing shed and the new addition received Trusscore wall panels, creating a clean, washable, and long-lasting surface ideal for food-safe or utility use.

Outside, we updated both sections of the building with new steel wall panels and custom metal trims to give the honey extraction shed a cohesive, modern appearance. This renovation blends new construction with an upgrade of an existing agricultural structure—delivering a fully insulated, low-maintenance workspace built to handle seasonal honey processing or general farm use.

The roof of the original building was spray foamed to allow the open webbing of the trusses to stay exposed and allow more storage.

The walls of the addition were spray foamed to ensure an air tight seal on the extraction room walls to make it easy to heat and keep out any bees during the honey extraction process.

from Durham did a super clean install on these 50,000 BTU Propane heaters from

. Two heaters where installed on separate thermostats to allow the heating to be controlled in the extraction room, and shop/storage areas separately

PVC Liner is being installed on the ceiling and walls of the extraction room. Its a food grade liner, which is smooth and easy to clean, and white keeping the room bright. Also this liner is manufactured in Palmerston, ON allowing us to support local business.

Steel Siding & Insulation Underway – Southgate Honey Shed Build

Wall steel is going up on our honey shed addition in Southgate, located just south of Durham between Holstein and Mount Forest. It’s always exciting to see color hit the building—this custom steel siding from Keupfer really pulls the structure together. The new siding gives the honey extraction building a clean, professional finish that ties into the surrounding farm property.

Inside, we’re spray-foaming the new honey extraction room and using Roxul mineral wool insulation in the original section of the pole shed. We installed Typar house wrap behind the new wall steel to serve as a proper air barrier, ensuring the building envelope is sealed and energy-efficient. This mix of new build and renovation work reflects how we bring older sheds up to modern performance standards for rural homeowners and agricultural clients.

The remainder of the old wall steel will be taken off and the new steel will cover the entire building. The old steel will be reused on the interior of the original building which will be storage and work shop for the honey business.

We installed this 2" x 6" board in the open web of the old building to create a spot to route the new wiring as their will be no ceiling in this part and all the wiring in the trusses will be exposed.

We had trims made to trim out the contractor grade steel insulated doors, making a nice clean transition to the new wall steel. The doors were installed with no windows to make blacking out the building easier when certain aspects of the bee keeping business require a dark working space.

This is the new utility room in the building. This is where the water comes into the building, the new 100 amp electrical panel, and catch basin for the extraction room gutter drain is located. It will be lined with plywood to make it easy to mount all the utilities, and the hot water tank will be located.

This door opening is ready for the new

insulated overhead door. We cladded all the interior with white steel to match the new liner and make a very clean surface to mount the new door track too.