Roofing & Rough-In Stage Complete – Priceville Farmhouse Renovation

With rough-ins complete, we’ve now installed a full architectural shingle roofing system on this Priceville farmhouse restoration. We used GAF Timberline lifetime shingles for durability and curb appeal—ideal for this one-and-a-half-story heritage home in Grey County. Six feet of ice and water shield were applied in all eaves and valleys, with synthetic felt paper protecting the rest of the roof. Steel valley flashings were installed for added long-term performance, ensuring this farmhouse roof can handle another century of Ontario weather.

We also added a concealed vented ridge under the ridge cap, creating a continuous airflow path that doesn’t compromise the roofline’s traditional look. These roofing upgrades are a key part of restoring older farmhouses—tying modern protection into classic forms. As the general contractor on this project, JCB & SONS is managing every phase of this full-home renovation near Markdale and Durham, from structural framing to waterproofing and finish.

We also installed almost 400 brick ties in the old home tying the old structure into the new structure we built inside of it prior to polyurethane foam insulating.

We took the time to drywall the ceiling in the addition prior to insulating. We than had 2" of foam insulation sprayed over the drywall, potlights, speakers, etc. We will top this up with cellulose to achieve an R-50 in the addition attic. This ensures an airtight seal around all the fixtures and against the exposed brick wall between the old home and the addition.

We added this Pent Roof over the living room window which looked out of place prior to the renovation because it was added later and not trimmed the same. All the openings in the brick have arches except this one. This added an element of curve to this window, it should also tie in well with the future porch around the addition.

The addition foundation was cement block and leaked badly all the time, especially in the spring or after rains. We excavated around the foundation to waterproof it. We pressure washed the old foundation as well so the waterproofing would bond to a clean surface.

Hydro One came in and disconnect power and installed the new underground cable from the hydro pole at the road to the new meter base WireQ installed.

WireQ installed a disconnect switch to add in a future back up generator as well as a new 200amp breaker panel.

During excavating we found the missing well, which is illegal as it was below grade and would have run off going in the exposed well head. The cement block foundation had a lot of cracks. We V'd them out with a diamond blade and filled them with non-shrink grout which was than coated with fibreglass resin by MBS prior to tarring it.

We installed new septic tank risers on the old septic tank to make locating and cleaning the tank easy.

We eliminated the old sump pail by digging in this trench and installing pipe for the weeping tile and a separate pipe for eavestrough creating a french drain to remove the water far from the foundation.

The front door sill was all gone and rotten. We poured in a new cement sill after having the ring joist coated in spray foam first.

sprayed all the walls with R-24 spray foam, the old house sloped ceiling received R-50 spray foam and the addition received R-12 spray foam and will be topped up to R-50 with cellulose.

Martins Insulation insulated the basement walls with R-24 Spray foam.

We tied the new weeping tile into our new french drain, which we also installed a cleanout in just in case. We ran a separate line than to tie the eavestrough into.

We than backfilled the foundation with 2' of washed stone and than gravel on top to ensure great drainage around the foundation as the property does slope into this home.

The white pipe on the left is the cleanout for the weeping tile ensuring it can never plug. The white pipe on the right is for the future eavestrough to tie into. Keeping the water away from the basement.

Framing Reinforcement & Mechanical Rough-Ins – Priceville Farmhouse Reno

At this stage of our Priceville farmhouse renovation, we tackled both structural upgrades and mechanical rough-ins. We installed a new breathable house wrap to protect the wall assembly from moisture while allowing it to dry properly—essential in any heritage restoration. This vapor-open barrier creates a strong line of defense before new siding is installed, especially for older rural homes like this one-and-a-half-story farmhouse in Grey County.

On the framing side, we reinforced the roof structure with new collar ties and added 2x ceiling joists to bring the system back into alignment. Over the decades, the original roof had begun to sag slightly—a common issue in heritage homes. The new framing not only braces the house for future loads, but also locks everything in place for the next 100 years. As general contractor and builder on this project, JCB & SONS continues to handle every phase of this restoration—from demolition to finish—with structural integrity and craftsmanship.

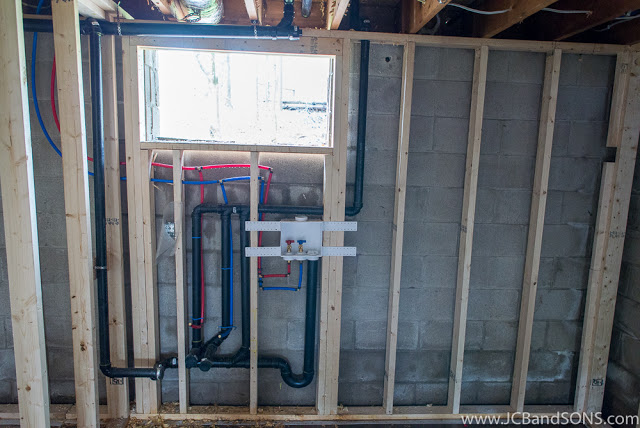

The basement walls are all framed up and ready for all the wiring, plumbing, insulation.

Because of the span on the rafters we also strapped all the ceiling with 2" x 4" @ 16" o.c. to install our drywall. This also further contributes to tying the old walls together and strengthening the old roof.

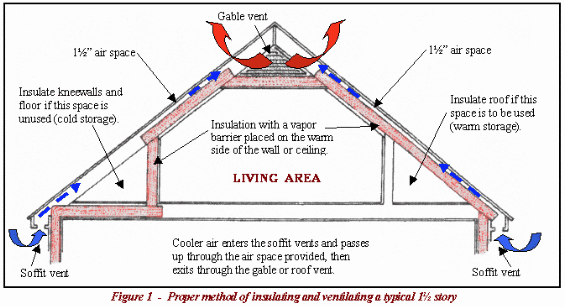

The pink things in the roof are

. These are a must to allow an air space between your insulation and roof sheathing. It allows your attic to vent properly thus preventing

1 and also making your shingles last much longer.

The one bedroom and bathroom will be receiving pocket doors. The entire second floor will be receiving spray foam insulation.

The back half of the roof has been stripped of all the old shingles and the roof sheathing has been repaired and re-nailed. We installed two runs of

along the eaves and also one run in the valley's. We covered the remainder of the roof in

. This meets Ontario Building Code, keeps the house dry until shingled, and also meets the shingle manufactures requirements to be covered under their warranty. If the roof fails prematurely and this isn't done you will not be covered under warranty.

All of the heat runs and cold air returns are in for the first and second floors. The landing is also in for the new stairs.

This wall is for the laundry shoot and also created a chase for the main plumbing stack for the house.

has done an awesome job or wiring our project up, they will be roughing in for an alarm system, central vac, as well as a generator back up.

All of our plumbing rough in is in and passed inspection this week ready for insulation and drywall.

is installing an awesome high efficiency propane furnace,

, air conditioning. This will have the home comfortable all year round and with healthy clean air to breath.

We all started young in the Bender family on a broom. Clean job sites are important to us!

Restoration Framing on Heritage Farmhouse – Priceville, Ontario

This stage of our Priceville farmhouse restoration involved rebuilding from the foundation up—literally. The original stone and block foundation was far from level, which is typical of heritage homes in rural Ontario. We installed new pressure-treated sill plates and used non-shrink grout to fill irregular gaps, creating a solid, level base for framing. This is where restoration meets precision carpentry—laying the groundwork for a stable, long-lasting rebuild.

To protect the new structure from moisture over time, we installed gasketing between the pressure-treated sill plates and the existing foundation. This prevents future rot and ensures long-term durability. As general contractor and builder on this project, JCB & SONS is handling every phase—from teardown to rebuild—with care, craftsmanship, and the experience needed to renovate historic homes properly.

New jack posts were installed on new footings and we installed a new flush beam for the floor which won't interfere with the air flow of the new HVAC system. All the joists were installed with proper joist hanger brackets and engineered nails.

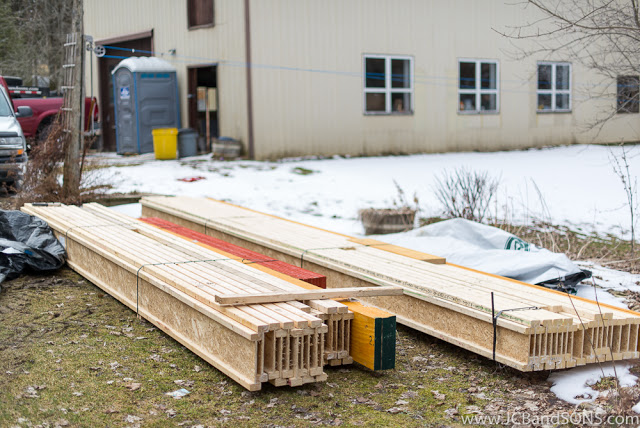

We will be using engineered Wood I's for the second floor, floor joists and the addition ceiling joists as they can clear span unsupported allowing the home to not have unsightly beams which would also interfere with duct work.

Gabriel and Jude are the Saturday crew and love to help make the dump runs.

We studded in the old basement and it's ready for the new polyurethane spray foam.

The old sheathing on the house was moldy and had to be removed, this also gave us the opportunity to use our tractor to pull the addition plumb as it was out a 1/2" and would make installing cabinets a problem had we not.

The new 5/8" tounge and groove sub-floor is glued and screwed to ensure no squeaks in the home.

This quick drive makes installing the sub-floor a breeze with its auto feeder.

LVL beams were installed in the second floor for the new stairs so that absolutely no walls or posts are needed in the room

The picture window in the old farmhouse was not original to the home, it also didn't match the height of the other windows and the lintels were installed improperly. We opened it back up and installed new lintels that were welded together for added strength.

The new ceiling joists are in so the roof sheathing was reinstalled and Grace Ice and Water Shield has been installed ready for the new shingles.

The new Wood I's are installed in the addition of the home allowing for an open concept kitchen and 10'-0" high ceilings too.

Also check out our latest video post: